Embedded Smart IC memory just got smarter, faster and more powerful using non-volatile FRAM (Ferroelectric Random Access Memory) technology. Lightening fast write speeds, inexhaustible write endurance and superior data reliability. FRAM-based smart ICs can be personalized, produced and programmed simply, quickly and more reliably than other types of IC memory.

TI’s next-generation smart IC platform will be faster, smaller, and able to write data more reliably than ever before. Learn how an embedded memory technology, called FRAM (Ferroelectric Random Access Memory), will dramatically increase the performance of new electronic government ID credentials.

FRAM, an acronym for ferroelectric random access memory, is a non-volatile memory that can hold data even after it is powered off. In spite of the name, FRAM is a ferroelectric memory and is not affected by magnetic fields as there is no ferrous material (iron) in the chip. Ferroelectric materials switch polarity in an electric field, but are not affected by magnetic fields.

1) Speed. FRAM has fast write times. Beyond all the other operations, the actual write time to an FRAM memory cell is less than 50ns. That is approximately 1000x faster than EEPROM. Additionally, unlike EEPROM where you must have two steps to write data: a write command, followed by a read/verify command; FRAM’s write memory function happens in the same process as read memory. There is only one memory access command, one step for either reading or writing. So in effect, all the time associated with an EEPROM write transaction is effectively eliminated in an FRAM-based smart IC.

2) Low Power. Writes to the FRAM cell occur at low voltage and very little current is needed to change the data. With EEPROM high voltages are needed. FRAM uses very low power – 1.5v compared to 10-14v for EEPROM. FRAM’s low voltage translates into low power usage and enables more functionality at faster transactions speeds.

3) Data Reliability. Because only a small amount of energy is required, all the necessary power for FRAM is front-loaded at the beginning of data write. This avoids “data-tearing,” a partial write of the data which occurs when EEPROM based smart ICs are removed from the RF field power source during a write cycle. Further, FRAM experiences 100 Trillion read/write cycles or greater – far exceeding EEPROM write cycles.

FRAM is a very robust and reliable memory technology, even at high temperatures. FRAM retains its data for more than 10 years at 85 degrees C. This far exceeds the requirements for credentials in the government ID market and represents the robust data retention of FRAM. FRAM is used in several automotive applications and has been qualified to withstand the extremely harsh conditions.

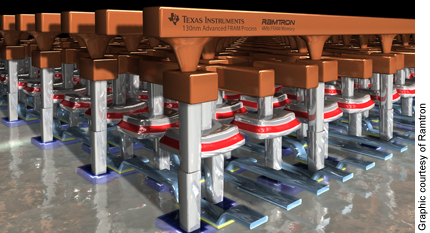

Unlike FRAM, EEPROM employs a floating gate charge storage design which necessitates high voltage and costly, power-hungry and space-hogging circuits, such as transistors and charge pumps. A restriction of all this high-voltage legacy circuitry is that it does not easily scale to smaller and smaller IC process node manufacturing. TI's advanced 130 nanometer (nm) FRAM manufacturing process results in chips that are much smaller than the 180 – 220 nm node sizes used by in most EEPROM-based contactless smart ICs, giving FRAM products a significant advantage in size, performance, and power efficiency. Further, the FRAM manufacturing process is fully compatible with digital CMOS processes making the technology easy to scale to smaller technology nodes in the future.

No. FRAM is a nonvolatile storage memory that retains its data even after the power is turned off. Similar to commonly used DRAM (Dynamic Random Access Memory) found in large (main) memories in personal computers, workstations, and non-handheld game-consoles (such as PlayStation and Xbox), FRAM requires a memory refresh after each read. A memory refresh is done because like DRAM, FRAM memory cells require each bit accessed to be re-written in a refresh function. Because FRAM has an inexhaustible write endurance (100 trillion write/read cycles), this is not a practical concern.

FRAM is already used in financial smartcard applications in transit and in set-top boxes. Compared to existing EEPROM technologies, FRAM is more resistant to data corruption via electric fields, radiation, etc. The extremely fast write times and the small 130 nanometer (nm) process node make it difficult for attackers. Furthermore, FRAM’s lower power consumption (and the fact that its read and write power consumption is identical) arguably make it a more difficult target to attack using differential power analysis techniques.

FRAM devices are ferroelectric memories and are not ferro-magnetic. They are not affected by external magnetic fields.

The FRAM memory cell operates by applying a switched voltage to sense and restore the data state. The ferroelectric film PZT is about 70nm thick. If the device is placed in a 50 kV field at 1 cm, it is not possible to produce more than 1V across the ferroelectric film. As a practical matter, FRAM devices are impervious to external electric fields.

Volatile memories, DRAM and SRAM, use a capacitor to store charge or a simple latch to store state. These cells can be easily upset by a alpha particles, cosmic rays, heavy ions, gamma, x-rays, etc. which cause bits to flip to an opposite state. This is called a soft error, since a subsequent write will be retained. The rate at which this occurs is called the Soft Error Rate (SER) of the device. Because the FRAM cell stores the state as a PZT film polarization, an alpha hit is very unlikely to cause the polarization to change a given cell’s state and the FRAM terrestrial SER is not even measurable.

Yes. F-RAM, FeRAM and FRAM are synonymous. Texas Instruments has chosen to use the acronym “FRAM” while Ramtron has chosen “F-RAM”.

FRAM is commercially proven in the semiconductor market with more than 150 million units sold by Ramtron alone. Ramtron’s F-RAM memory products have become a very popular choice in high quality industries such as automotive. Manufacturers such as Mercedes, GM, BMW, Ford, Porsche, and others, are now using FRAM in their automobiles. TI is producing Ramtron’s 4-Mb FRAM memory on its advanced 130-nanometer (nm) FRAM manufacturing process. Ramtron’s 4-Mb FRAM memory product was named 2008 Product of the Year by Electronic Products China (EPC) Magazine.