Copyright Michael Karbo and ELI Aps., Denmark, Europe.

Chapter 27. Inside and around the CPU

In this and the following chapters, I will focus on a detailed look at the CPU. One of the goals is help to you understand why manufacturers keep releasing new and more powerful processors. In order to explain that, we will have to go through what will at times be a quite detailed analysis of the CPU’s inner workings.

Some of the chapters will probably be fairly hard to understand; I have spent a lot of time myself on my “research”, but I hope that what I present in these chapters will shed some light on these topics.

Naturally, I will spend most of my time on the latest processors (the Athlon XP and Pentium 4). But we need to examine their internal architectures in light of the older CPU architectures, if we want to understand them properly. For this reason I will continually make comparisons across the various generations of CPU’s.

Inside the CPU

I will now take you on a trip inside the CPU. We will start by looking at how companies like Intel and AMD can continue to develop faster processors.

Two ways to greater speed

Of course faster CPU’s are developed as a result of hard work and lots of research. But there are two quite different directions in this work:

Both approaches are used. It is a well-known fact that bottlenecks of various types drain the CPU of up to 75 % of its power. So if these can be removed or reduced, the PC can become significantly faster without having to raise the clock frequency dramatically.

It’s just that it is very complicated to remove, for example, the bottleneck surrounding the front side bus, which I will show you later. So the manufacturers are forced to continue to raise the working rate (clock frequency), and hence to develop new process technology, so that CPU’s with more power can come onto the market.

Clock frequencies

If we look at a CPU, the first thing we notice is the clock frequency. All CPU’s have a working speed, which is regulated by a tiny crystal.

The crystal is constantly vibrating at a very large number of “beats” per second. For each clock tick, an impulse is sent to the CPU, and each pulse can, in principle, cause the CPU to perform one (or more) actions.

Figure 54. The CPU’s working speed is regulated by a crystal which “oscillates” millions of times each second.

The number of clock ticks per second is measured in Hertz. Since the CPU’s crystal vibrates millions of times each second, the clock speed is measured in millions of oscillations (megahertz or MHz). Modern CPU’s actually have clock speeds running into billions of ticks per second, so we have started having to use gigahertz (GHz).

These are unbelievable speeds. See for yourself how short the period of time is between individual clock ticks at these frequencies. We are talking about billionths of a second:

|

Clock frequency |

Time period per clock tick |

|

133 MHz |

0.000 000 008 000 seconds |

|

1200 MHz |

0.000 000 000 830 seconds |

|

2 GHz |

0.000 000 000 500 seconds |

Figure 55. The CPU works at an incredible speed.

The trend is towards ever increasing clock frequencies. Let’s take a closer look at how this is possible.

More transistors

New types of processors are constantly being developed, for which the clock frequency keeps getting pushed up a notch. The original PC from 1981 worked at a modest 4.77 MHz, whereas the clock frequency 20 years later was up to 2 GHz.

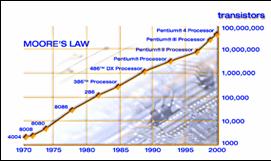

In Fig. 56 you can see an overview of the last 20 years of

development in this area. The table shows the seven generations of Intel

processors which have brought about the PC revolution. The latest version of

Pentium 4 is known under the code name

|

Gen. |

CPU |

Yr |

Clock |

No. of |

|

1 |

8088 |

1979 |

4.77- 8 MHz |

29,000 |

|

2 |

80286 |

1982 |

6-12.5 MHz |

134,000 |

|

3 |

80386 |

1985 |

16-33 MHz |

275,000 |

|

4 |

80486 |

1989 |

25-100 MHz |

1,200,000 |

|

5 |

Pentium |

1993 |

60-200 MHz |

3,100,000 |

|

6 |

Pentium

Pro |

1995 |

150-200 MHz |

5,500,000 |

|

7 |

Pentium

4 |

2000 |

1400-2200 |

42,000,000 |

Figure 56. Seven generations of CPU’s from Intel. The number of transistors in the Pentium III and 4 includes the L2 cache.

Each processor has been on the market for several years, during which time the clock frequency has increased. Some of the processors were later released in improved versions with higher clock frequencies, I haven’t included the Celeron in the overview processor. Celerons are specially discount versions of the Pentium II, III, and 4 processors.

Anyone can see that there has been an unbelievable development. Modern CPU’s are one thousand times more powerful than the very first ones.

In order for the industry to be able to develop faster CPU’s each year, new manufacturing methods are required. More and more transistors have to be squeezed into smaller and smaller chips.

|

|

Figure 57. |

Moores

This development was actually described many years ago, in what we call Moores Law.

|

Right back in 1965, Gordon Moore predicted (in the Electronics journal), that the number of transistors in processors (and hence their speed) would be able to be doubled every 18 months. |

Figure 58. In 1968, Gordon Moore helped found Intel. |

If we try to look ahead in time, we can work out that in 2010 we should have processors containing 3 billion transistors. And with what clock frequencies? You’ll have to guess that for yourself.

Figure 59.

Process technology

The many millions of transistors inside the CPU are made of, and connected by, ultra thin electronic tracks. By making these electronic tracks even narrower, even more transistors can be squeezed into a small slice of silicon.

The width of these electronic tracks is measured in microns (or micrometers), which are millionths of a metre.

For each new CPU generation, the track width is reduced, based on new technologies which the chip manufacturers keep developing. At the time of writing, CPU’s are being produced with a track width of 0.13 microns, and this will be reduced to 0.09 and 0.06 microns in the next generations.

Figure 60. CPU’s are produced in extremely high-technology environments (“clean rooms”). Photo courtesy of AMD.

In earlier generations aluminium was used for the current carrying tracks in the chips. With the change to 0.18 and 0.13-micron technology, aluminium began to be replaced with copper. Copper is cheaper, and it carries current better than aluminium. It had previously been impossible to insulate the copper tracks from the surrounding silicon, but IBM solved this problem in the late 1990’s.

AMD became

the first manufacturer to mass-produce CPU’s with copper tracks in their chip

factory fab

Figure 61. AMD’s Fab 30 in Dresden, which was the first factory to mass-produce copper-based CPU’s.

A grand new world …

We can expect a number of new CPU’s in this decade, all produced in the same way as they are now – just with smaller track widths. But there is no doubt that we are nearing the physical limits for how small the transistors produced using the existing technology can be. So intense research is underway to find new materials, and it appears that nanotransistors, produced using organic (carbon-based) semiconductors, could take over the baton from the existing process technology.

Bell Labs

in the

Less power consumption

The types of CPU’s we have today use a fairly large amount of electricity when the PC is turned on and is processing data. The processor, as you know, is installed in the motherboard, from which it receives power. There are actually two different voltage levels, which are both supplied by the motherboard:

As the track width is reduced, more transistors can be placed within the same area, and hence the voltage can be reduced.

As a consequence of the narrower process technology, the kernel voltage has been reduced from 3 volts to about 1 volt in recent years. This leads to lower power consumption per transistor. But since the number of transistors increases by a corresponding amount in each new CPU generation, the end result is often that the total power consumption is unchanged.

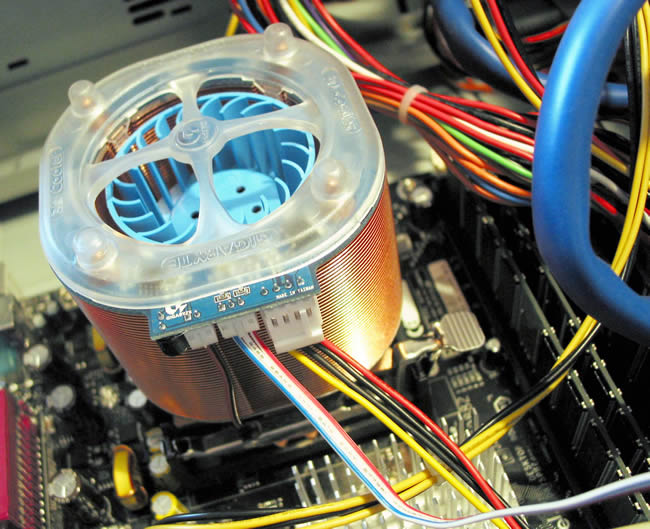

Figure 62. A powerful fan. Modern CPU’s require something like this.

It is very important to cool the processor; a CPU can easily burn 50-120 Watts. This produces a fair amount of heat in a very small area, so without the right cooling fan and motherboard design, a Gigahertz processor could quickly burn out.

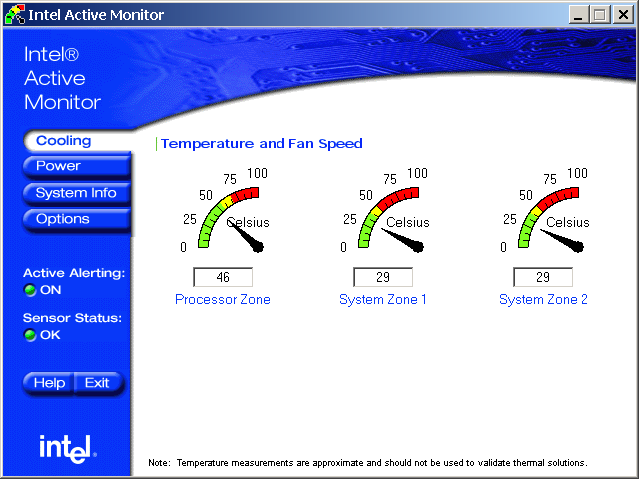

Modern processors contain a thermal diode which can raise the alarm if the CPU gets to hot. If the motherboard and BIOS are designed to pay attention to the diode’s signal, the processor can be shut down temporarily so that it can cool down.

Figur Figure 63. The temperatures on the motherboard are constantly reported to this program..

Cooling is a whole science in itself. Many “nerds” try to push CPU’s to work at higher clock speeds than they are designed for. This is often possible, but it requires very good cooling – and hence often huge cooling units.

30 years development

Higher processor speeds require more transistors and narrower electronic tracks in the silicon chip. In the overview in Fig. 64 you can see the course of developments in this area.

Note that the 4004 processor was never used for PC’s. The 4004 was Intel’s first commercial product in 1971, and it laid the foundation for all their later CPU’s. It was a 4-bit processor which worked at 108 KHz (0.1 MHz), and contained 2,250 transistors. It was used in the first pocket calculators, which I can personally remember from around 1973-74 when I was at high school. No-one could have predicted that the device which replaced the slide rule, could develop, in just 30 years, into a Pentium 4 based super PC.

If, for

example, the development in automobile technology had been just as fast, we

would today be able to drive from

|

Year |

Intel CPU |

Technology (track width) |

|

1971 |

4004 |

10 microns |

|

1979 |

8088 |

3 microns |

|

1982 |

80286 |

1.5 microns |

|

1985 |

80386 |

1 micron |

|

1989 |

80486 |

1.0/0.8 microns |

|

1993 |

Pentium |

0.8/0.5/0.35 microns |

|

1997 |

Pentium II |

0.28/0.25 microns |

|

1999 |

Pentium III |

0.25/0.18/0.13 microns |

|

2000-2003 |

Pentium 4 |

0.18/0.13 microns |

|

2004-2005 |

Pentium

4 |

0.09 microns |

Figure 64. The high clock frequencies are the result of new process technology with smaller electronic ”tracks”.

A conductor which is 0.09 microns (or 90 nanometres) thick, is 1150 times thinner than a normal human hair. These are tiny things we are talking about here.

Wafers and die size

Another CPU measurement is its die size. This is the size of the actual silicon sheet containing all the transistors (the tiny area in the middle of Fig. 33 on page 15).

At the chip factories, the CPU cores are produced in so-called wafers. These are round silicon sheets which typically contain 150-200 processor cores (dies).

The smaller one can make each die, the more economical production can become. A big die is also normally associated with greater power consumption and hence also requires cooling with a powerful fan (e.g. see Fig. 63 on page 25 and Fig. 124 on page 50).

Figur Figure 65. A technician from Intel holding a wafer. This slice of silicon contains hundreds of tiny processor cores, which end up as CPU’s in everyday PC’s.

You can see the measurements for a number of CPU’s below. Note the difference, for example, between a Pentium and a Pentium II. The latter is much smaller, and yet still contains nearly 2˝ times as many transistors. Every reduction in die size is welcome, since the smaller this is, the more processors can fit on a wafer. And that makes production cheaper.

|

CPU |

Track width |

Die size |

Number of |

|

Pentium |

0.80 |

294 mm2 |

3.1 mil. |

|

Pentium MMX |

0.28 |

140 mm2 |

4.5 mil. |

|

Pentium II |

0.25 |

131 mm2 |

7.5 mil. |

|

Athlon |

0.25 |

184 mm2 |

22 mil. |

|

Pentium III |

0.18 |

106 mm2 |

28 mil. |

|

Pentium III |

0.13 |

80 mm2 |

28 mil. |

|

Athlon XP |

0.18 |

128 mm2 |

38 mil. |

|

Pentium 4 |

0.18 |

217 mm2 |

42 mil. |

|

Pentium 4 |

0.13 |

145 mm2 |

55 mil. |

|

Athlon XP+ |

0.13 |

115 mm2 |

54 mil. |

|

Athlon 64 FX |

0,13 |

193 mm2 |

106 mill. |

|

Pentium 4 |

0.09 |

112 mm2 |

125 mil. |

Figure 66. The smaller the area of each processor core, the more economical chip production can be.

The modern CPU generations

As mentioned earlier, the various CPU’s are divided into generations (see also Fig. 56 on page 23).

At the time of writing, we have started on the seventh generation. Below you can see the latest processors from Intel and AMD, divided into these generations. The transitions can be a bit hazy. For example, I’m not sure whether AMD’s K6 belongs to the 5th or the 6th generation. But as a whole, the picture is as follows:

|

Generation |

CPU’s |

|

5th |

Pentium, Pentium MMX, K5, K6 |

|

6th |

Pentium Pro, K6-II, Pentium II, K6-3, Athlon, Pentium III |

|

7th |

Pentium 4, Athlon XP |

|

8th. |

Athlon 64 FX, Pentium 5 |

Figure 67. The latest generations of CPU’s.