|

The Spartan™ series of FPGAs (Spartan-II, Spartan-XL, and Spartan

families) provides an effective ASIC production solution for many

gate array designs. Derived from the successful Xilinx XC4000 and

Virtex architectures and supporting up to 200,000 system gates, the

Spartan series combines low ASIC production pricing with ASIC

features such as on-chip RAM, low power, high performance and a

robust selection of silicon-verified cores. The Spartan series is

the first FPGA that meets all of the key cost, feature and

performance criteria to realistically replace mask gate arrays in

production. The Spartan series simply provides FPGA flexibility at

ASIC prices!

ASIC Features

- On-chip SelectRAM dual port synchronous memory, placed at any

location

- High performance - 80 MHz to 200 MHz system speeds

- Extensive verified portfolio of cores with AllianceCORE and

LogiCORE products

- Built-in IEEE 1149.1 Boundary Scan support

- Low-power design permits Spartan devices to use inexpensive

plastic packages

- Comprehensive Verilog and VHDL software support featuring

Xilinx partners

ASIC Pricing

Xilinx can offer ASIC production pricing because the Spartan

series has substantially reduced the die size and manufacturing

costs. Cost targets were realized by using an advanced fabrication

process and streamlining the FPGA features. Spartan series die has

been decreased to limits imposed by the I/O pads and, as a result,

has reached die size parity with many gate arrays. The Spartan FPGA

and a mask ASIC with the same number of pins are equivalent in both

size and cost. Spartan FPGAs offer volume production prices as low

as $2.49 for Spartan-XL devices (5,000 system gates) and less than

$10.00 for 100,000 gate Spartan-II devices.

Major ASIC Vendors Exit the Gate Array Business

The mask ASIC is actually penalized when migrating to the

advanced deep sub-micron technologies at 0.35 mm and beyond. The penalty occurs because the

transistors in deep sub-micron devices have shrunk much faster than

metal lines. The result is that interconnect delay now dominates

gate delay. Minimizing interconnect delay requires adding metal mask

layers to create more routing resources. Each photo mask for the

0.35-mm process costs the ASIC supplier

from $12,000-$15,000, as well as extending the prototype fab time.

Since most ASICs today are fabricated with four or five custom metal

layers, a $60,000-$75,000 cost for photo masks for each different

customer design easily results in more than $100,000 in

Non-Recurring Engineering (NRE) charges to the customer! The

Spartan FPGA does not incur the same cost penalties of ASICs because

each photo mask is created only once over the lifetime of the

programmable device and serves hundreds of different customers.

A deep sub-micron gate array loses much of its value when NREs are

increased to more than $100,000 and prototype time is extended. This

is a primary reason that gate array vendors such as LSI Logic and

Motorola have exited the gate array business to focus on the complex

Standard Cell market.

Total Cost Management Program

Spartan FPGAs also apply an aggressive Total Cost Management

Program to hold product costs low. For example, the Xilinx Spartan

series has

- Limited the number of family members

- Supported a very focused offering of inexpensive plastic

packages

- Optimized the test flow to reduce back end costs

Qualifying Gate Array Design for a Good FPGA Fit

The graph below plots the Spartan series parts according to

system gates and number of I/O. As indicated, Spartan FPGAs are most

cost-competitive in the low-density/high I/O (lower right) segment.

The graph may be used as a reliable indicator to determine where the

Spartan FPGAs can be most competitive with the ASIC in mass

production. In short, when the Spartan FPGAs have the same number of

I/Os as the ASIC and meet the density needs of your design, the FPGA

will clearly be a better choice. By choosing Spartan devices you

receive the time-to-production and reprogrammability advantages of

FPGAs at ASIC prices. For higher densities and I/O counts, consider

the Xilinx Virtex series.

Immediate Production

A fast ramp to full production is a primary advantage of these

ASIC Replacement FPGAs. Spartan series deliveries are off the shelf

from the Xilinx factory or from the inventory of our distribution

partners, while typical ASIC lead times run from 8-16 weeks.

Immediate Spartan FPGA production enables fast stocking of your

sales channels and the rapid penetration of your customer base.

Spartan FPGAs help you avoid the delays resulting from the long ASIC

lead times that may substantially decrease revenues and profits

throughout the life of the product. A well-known McKinsey study

found that a six month delay costs one third of the profits over the

lifetime of the product.

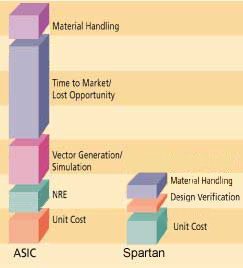

No FPGA Conversions for Spartan Series Users

The ASIC prices of Spartan series devices eliminate the need for

low-density FPGA conversions to mask gate arrays. The Spartan FPGA

user speeds time-to-production, minimizes development/NRE costs, and

avoids unnecessary re-design risks by foregoing an FPGA-to-ASIC

redesign.

Turnaround time:

- FPGA to ASIC conversions take a minimum of four months to

production. The typical breakdown is the following:

- Conversion time - 3 weeks average

- Prototype time - 3 weeks best case

- ASIC full production lead time - 8-16 weeks

- Total conversion time-to-production = 4 months or

more!

Costs:

- NRE/conversion fees - ~$10,000-$30,000

- Cost of your internal conversion engineering efforts -

~$20,000

- Simulate and verify redesign

- Qualify prototypes

- Transfer into production

|

| Conversion Redesign

Risks:

- Converting FPGA features such as on-chip RAM, scan, reset,

etc.

- Netlist changes adding new buffers and new I/O drive

capabilities

- Change of timing to new ASIC architecture

- Porting of FPGA cores - complex licensing issues moving to new

platform

The New FPGA Paradigm: No Costly FPGA

Conversion Needed

- Spartan FPGAs are intended for fast development and

cost-effective production

- Advantages of the FPGA in mass production:

- No conversion engineering effort

- No NRE or conversion fees

- Cost reduction path through future generations

- Immediate volume production!

Converging HDL Design Methodologies

Historically, programmable logic development methodology has

lagged the ASIC industry by at least five years. This gap began to

narrow in the early 1990s with the adoption of VHDL by a few PLD

designers for more complex designs. As FPGAs continued to grow in

density beyond the 20,000 gate level, the schematic design approach

began to falter. It became obvious that implementation of VHDL

support, and later Verilog support, would be necessary for the

programmable vendors to continue offering greater device density and

to provide the ASIC designer with a familiar design environment.

ASIC and FPGA Converging Design Approach

Today, the design methodologies have converged to the extent both

ASIC and Xilinx FPGA design flows support behavioral simulation,

extensive use of cores, RTL synthesis, timing and functional

simulation, static timing analysis, floorplanning, etc. Xilinx has

added other widely used ASIC-like tools such as minimum delay timing

reports, more comprehensive static timing, team approach modular

design and much more.

Xilinx HDL Training for Programmable Logic

Xilinx FAEs are available to work with ASIC designers to ease the

learning curve of programmable designs. In addition, Xilinx offers

formal instruction in HDL design through Xilinx

training courses.

Comparing ASIC and Spartan FPGA HDL Design Flows

|

Spartan Family Choices

|

Spartan-II

|

Spartan-XL

|

Spartan

|

Gates plus

System-Level Features

|

Lowest Cost,

Low Power |

5V Supply |

| Max System Gates |

15,000 to 200,000 |

5,000 to 40,000 |

| Logic Gates |

6,000 to 100,000 |

2,000 to 13,000 |

| Block RAM |

16K to 56K bits |

N/A |

| I/O Perf. |

200 MHz + 4 DLLs |

100 MHz |

80 MHz |

| Max I/O |

86 to 284 |

77 to 224 |

77 to 205 |

| Supply Voltage |

2.5V |

3.3V |

5V |

| I/O Standards |

16 |

4 |

2 |

Spartan-II

Family Product Overview

Spartan-XL

Family Product Overview

Spartan

Family Product Overview

|